TSX: NEXT|OTCQB: NSRCF

TSX: NEXT|OTCQB: NSRCF

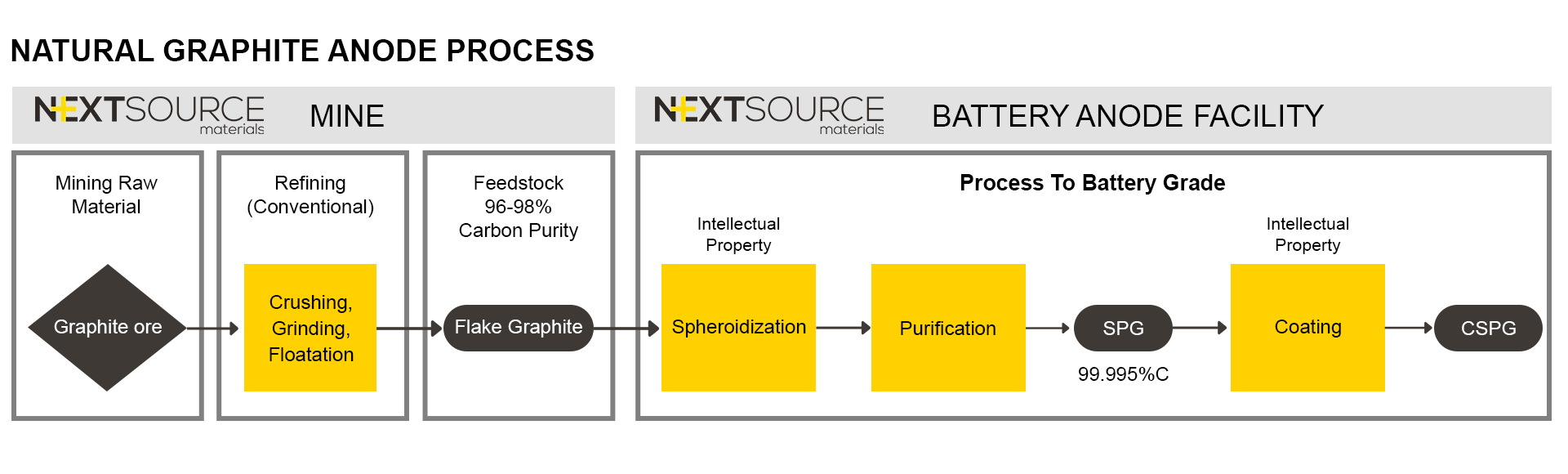

To meet rapidly growing demand for anode material for lithium-ion batteries used in electric vehicles, NextSource has secured an exclusive international partnership to develop turn-key processing facilities, called Battery Anode Facilities (BAFs).

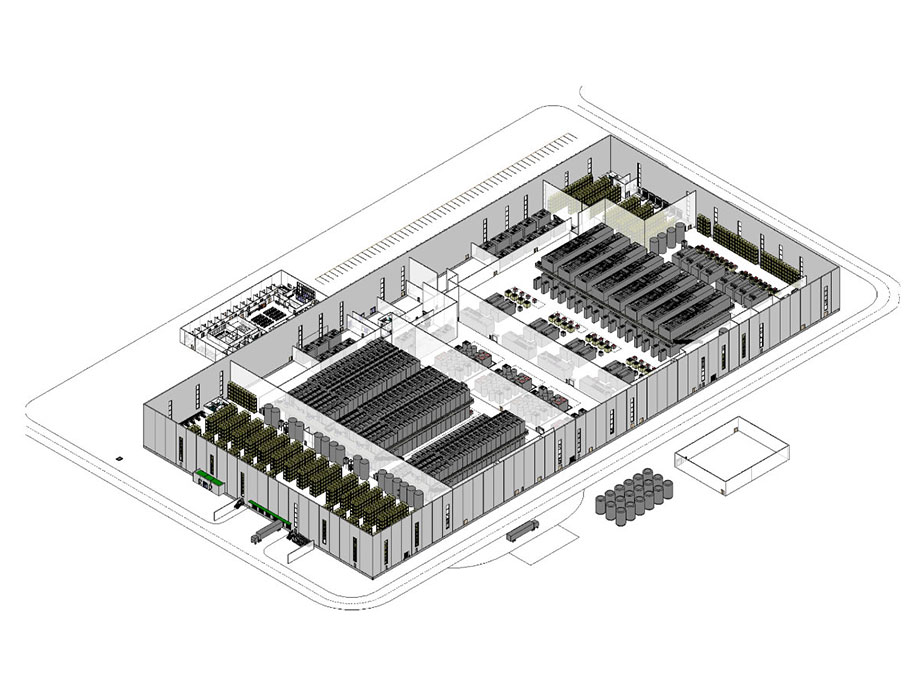

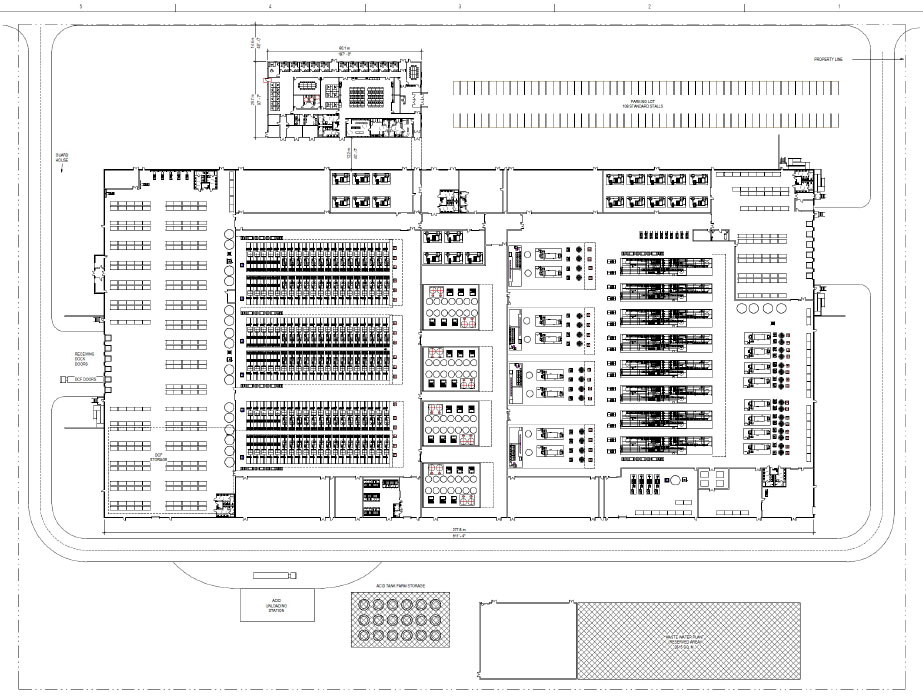

NextSource is planning a staged buildout of a series of BAFs in key geographic locations, each designed with modular production capacities that can expand in lockstep with automotive (OEM) demand from key markets in Asia, North America, Europe and the UK.

Each BAF uses an innovative design based on a proprietary and well-established processing technology that NextSource has exclusive license to, and is currently used to supply spheronized, purified graphite (SPG) to major OEMs. In addition, the BAFs will use a coating process verified by the Toyota and Tesla supply chain to produce coated SPG (CSPG). You can find out more about CSPG here.

The BAFs will source flake graphite from the Molo Graphite Mine and, if required and where appropriate, from qualified flake graphite feedstock of third parties.

To make CSPG, flake graphite concentrate is reduced to micron size, then mechanically shaped into spheres (spheroidization) and then purified. The spherical, purified graphite (SPG) material is then coated with a hard carbon shell that protects the sphere from exfoliation and degradation.

SPG production is dominated by Chinese firms who possess much of the Intellectual Property (IP) and expertise required to refine flake graphite into finished anode material.

NextSource has secured an exclusive partnership with two well-established and leading companies that process and supply leading Japanese anode and battery makers with anode material. Through this partnership, NextSource has an exclusive licence to best-in-class processing IP for SPG that is currently used in multiple OEM supply chains including Tesla and Toyota, and for a verified coating IP to produce CSPG.